When deciding on potential treatments it is important to consider the main aims and outcomes that are sought.

For this project, these are:

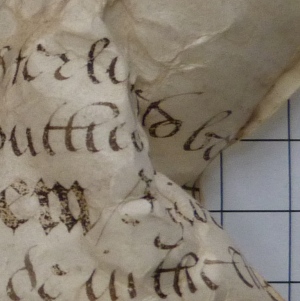

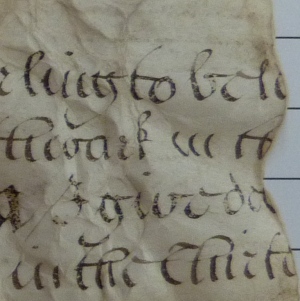

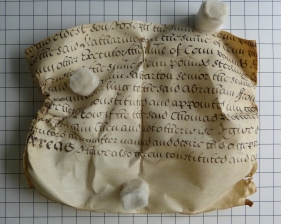

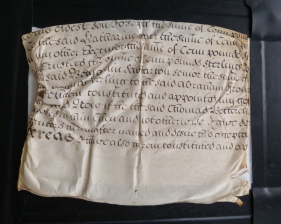

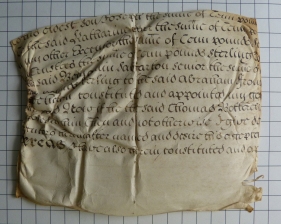

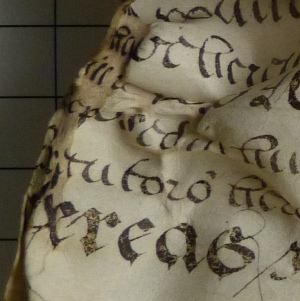

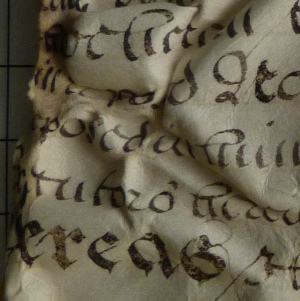

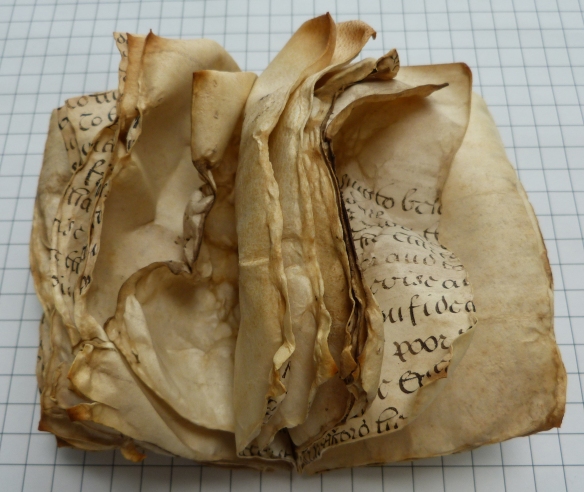

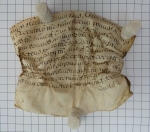

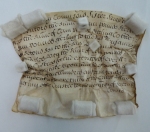

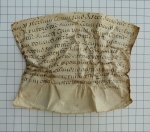

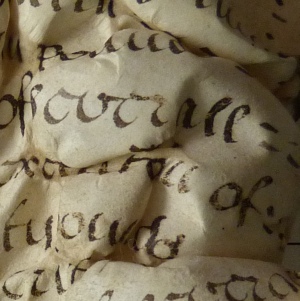

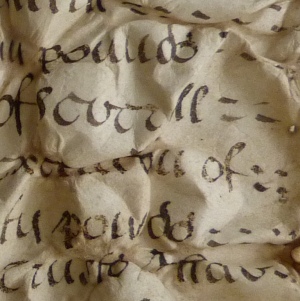

To remove creases so that hidden text is visible and can be photographed

To consolidate flaky media

To repackage sheets for safe storage

To use techniques that are ethical and involve minimal intervention

Solvents for humidification

To achieve the first goal, humidification will be necessary and so we have to decide which solvents will be used for this. The main ones in use are water and water/ethanol solutions which work by the vapours penetrating between the fibres and improving hydration. Latest research findings suggest that any use of either can have a detrimental effect on parchment fibres, but the extent of this is dependent on the type of fibre and its condition. Water and a water/ethanol solution will therefore be tested on samples for their effectiveness as humidification agents.

Amount of humidification necessary

Minimal intervention is critical and so it should be tested to see if just partial humidification of the worst areas is adequate for opening creases, or if full humidification is required. For partial humidification, the samples will be put in a damp blotter/Gore-Tex sandwich, interleaved with polyester to protect areas that are not to be humidified. The samples that are to be fully humidified will be placed on top of damp blotter and Gore-Tex in a covered tray.

Methods for tension drying

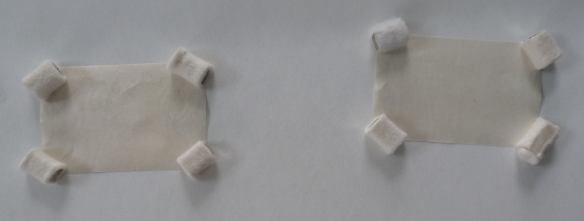

Magnets

The item is pinned out onto a metal sheet with magnets placed on the surface. This is an appropriate option for the GPB as it has pages with very torn, fragile edges. However, it is important to be aware of the strength of the magnets being used. Also, they can be quite brittle and can leave marks on parchment, so should be wrapped in a protective material such as felt or thick non-woven polyester.

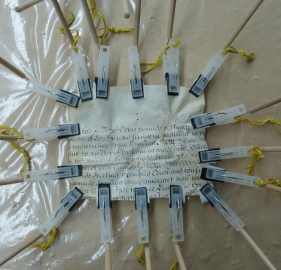

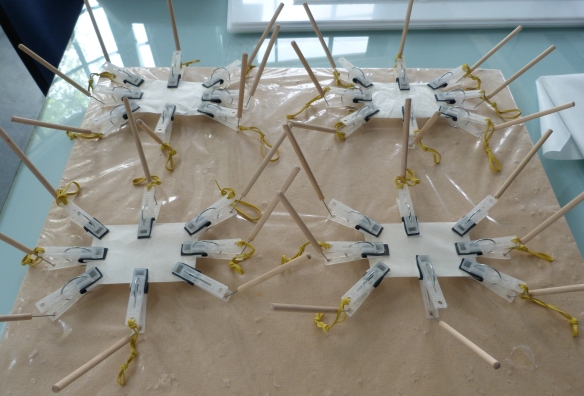

Pegging out

Pegs (or bull dog clips) are attached to the item edges and then tensioned out with pins. This method is appropriate for some of the less fragile pages of the GPB as the pegs can cause further damage to fragile edges.

Suction table

The item is held flat on the table while it dries. This could be an option, but might not be very effective on parchment that has areas that are very distorted and stiff, which the GPB has, as it relies on good contact with the table to allow flattening.

Pressing under boards

The item is placed under boards with weight on top. Given the amount of planar distortion in the GPB, this method would be totally inappropriate – creases would be pushed further into the parchment rather than pulled out. Also, problems have been seen in the past with this method causing the parchment to become transparent.

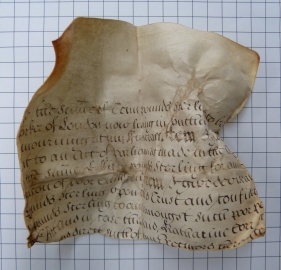

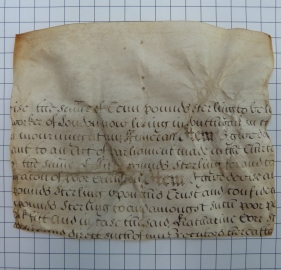

The next three posts will give details of trials to be carried out for humidification and crease reduction on three types of parchment. The first type is deliberately creased pieces of new parchment; the second is 19th century parchment, which will be deliberately heat damaged to replicate that seen on the GPB; the third is 17th century parchment with old heat damage caused by fire.